Step-by-step instructions for creating a homemade potato planter

Attachments can significantly increase the scope of application of walk-behind tractors and mini tractors. For example, a removable potato planter makes the process of planting vegetables easier. There are various models on sale, but you can make it yourself. We'll tell you how to make a potato planter with your own hands.

What is a potato planter

A potato planter is a special device used for precise and quick planting of potatoes. This technique is in great demand on farms.

Description and characteristics of the device

Different models may have additional mechanisms. But most units have similar designs:

- Furrow cutter. This is the part that creates the furrow for the potatoes. Usually the keel version is used. During movement, this element pushes the soil apart.

- Rippers. These parts loosen the soil compacted by the wheels or tracks of the tractor. They are mounted opposite the wheels on steel stands - behind all elements of the potato planter.

- Planting mechanism. Often the elevator type is used, which consists of a transport element and gripping parts. The latter scoop up the potatoes from the bottom of the hopper and move them into the planting tube of the opener.

There are also disc models where tuber turners and shaking doors are used to move potatoes. The turners are located at the bottom of the hopper at the exit.They are made in the form of a rotating shaft with “cams” that lift the flaps and move the tubers.

The productivity of the potato planter depends on the speed of movement. For tractor models, the operating speed is 4-10 km/h. In one hour, such units are capable of planting up to 1.3 hectares of potatoes. Options designed for walk-behind tractors have a productivity of up to 0.2 hectares per hour of operation, that is, one hundred square meters of area is processed in approximately 3-6 minutes. Manual planting will not give this result.

What is it for?

Thanks to the potato planter, work is greatly accelerated. The distance between rows and planting depth are automatically maintained. But such units are used only on previously prepared soil.

Reference. In addition to planting potatoes, the device is capable of performing other operations, for example, applying mineral fertilizers and treating tubers.

Application Features and Benefits

A homemade potato planter has the following advantages:

- Landing becomes easier, simpler and faster, despite soil structure.

- Planting is done at the same depth.

- The tubers in the row are distributed evenly.

- The device has high performance at low cost.

- If you use high-quality materials to make the unit, it will last for many years.

The planting speed is not affected by the potato variety. Thanks to the device, productivity increases, as it plants tubers evenly and at the same distance.

Read also:

Top leading countries in potato production worldwide.

The benefits and harms of potato broth.

Preparing the soil for planting potatoes: what soil acidity is needed.

Types and types of potato planters

Potato planters vary in size and type of tuber feeding.

To size

Small-sized ones are used for planting potatoes in a summer cottage or garden plot. The design provides a regulator for the depth and height of the earth ridge, which is formed when the soil is raised. Small devices suitable for walk-behind tractors. The hopper volume of such potato planters does not exceed 35 liters. The planting rate is 0.1-0.2 ha per hour.

For medium potato planters, the hopper volume reaches 45 liters, and the productivity is 0.25 hectares per hour. Such planters are installed on heavy walk-behind tractors and mini tractors.

Large ones are used for planting over large areas. Their bunker is correspondingly large and is loaded using a dump truck.

By type of seed supply

In a unit with a spoon system, potatoes are fed for planting using a structure of spoons attached to a belt.

The flat belt system consists of horizontally located belts between two main ones. This device produces a single-row planting.

The multi-belt system allows you to plant potatoes in two rows. Each row is served by several belts - up to 28 pcs.

Reference. When deciding which potato planter is better - belt or chain - you should take into account the fact that with the second, due to vibrations during operation, potatoes fall from the plate back into the hopper, and the planting turns out to be uneven.

How to make your own potato planter

Many vegetable growers and farmers prefer not to spend money, but to make potato planters with their own hands.

Required materials and tools

For production you will need:

- Corners and metal pipes from which the frame will be created.They are also needed for the installation of other structural elements.

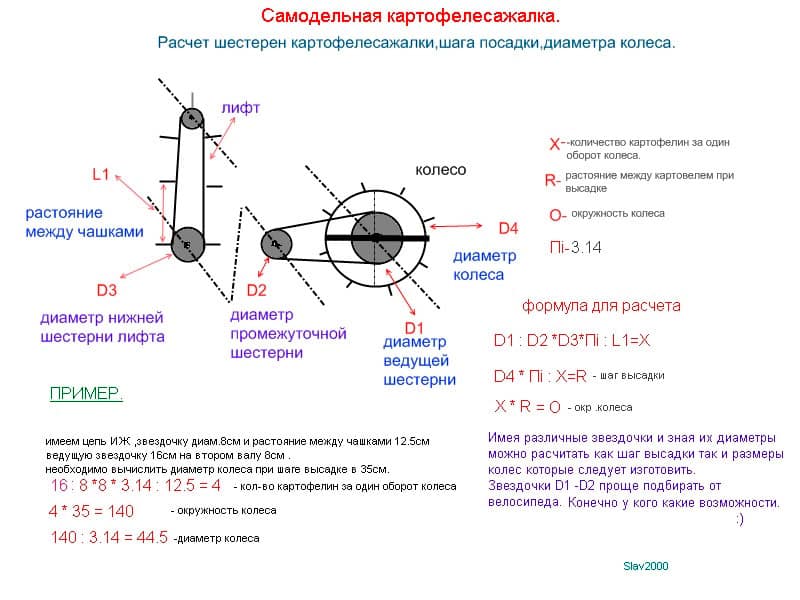

- Gears are elements that ensure the operation of the landing mechanism.

- Bunker for storing potatoes. Take a ready-made container or make it from sheet steel.

- Parts designed to create holes and bury them after planting.

- Wheelbase.

The listed elements are mandatory for a home potato planter. They are made independently or removed from old agricultural equipment.

To work you will need:

- Bulgarian;

- welding machine;

- spars;

- channels;

- pair of axes;

- bearings;

- chain from a car engine;

- two sprockets for the chain;

- wire with a cross section of 6 mm;

- sheet metal 2 mm thick;

- profile steel pipe;

- any cone-shaped container for a bunker.

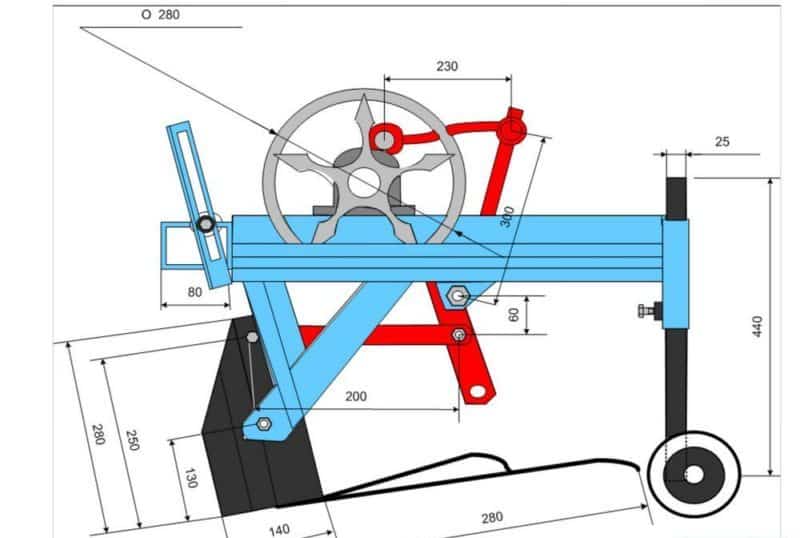

Drawings, dimensions and main elements

Externally, a homemade potato planter looks like a cart on wheels attached to a walk-behind tractor or mini tractor. Let's look at what the simplest design consists of.

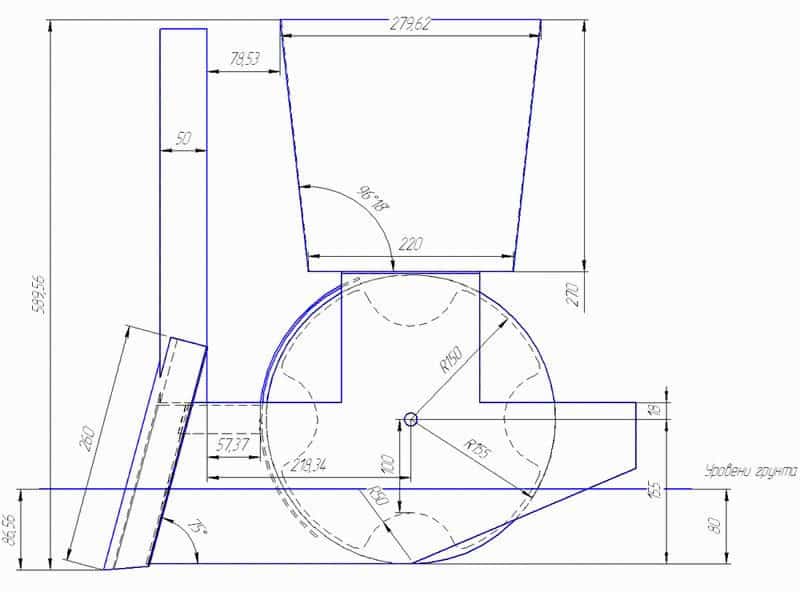

The “trolley” is placed on a frame made of channels. A steel arch and fork are mounted to its front part. On the sides of the frame, stands of closing discs and supports for the tuber feeding system are installed.

Important! Closing discs are an important element. Thanks to them, the furrows are even, and the potatoes are not buried more than necessary.

The frame, in turn, is installed on an axle with two wheels with a width of at least 15 mm, equipped with lugs. Simple rubber wheels will not work as they will slip.

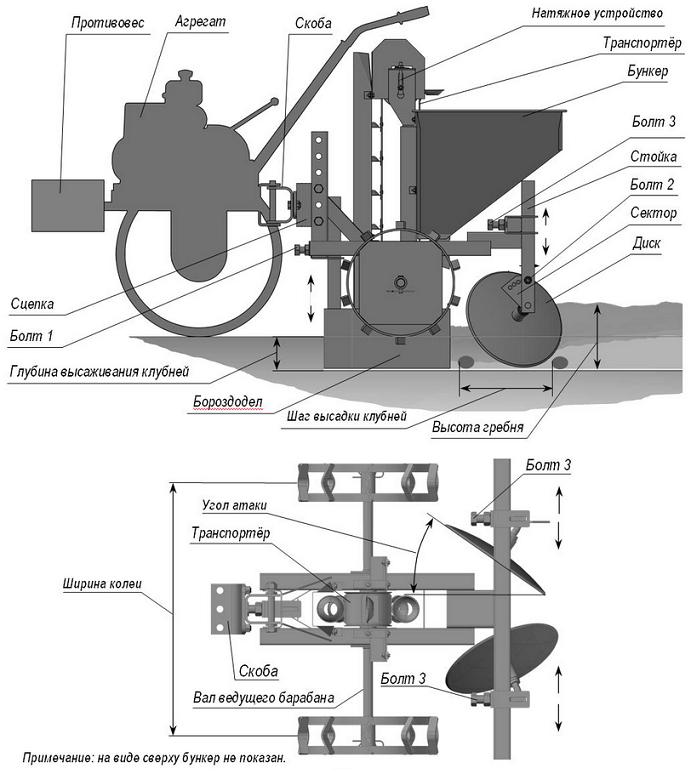

Using ready-made drawings with dimensions, you can make a cool potato planter with your own hands, practically from scrap metal (see photos 1, 2, 3, 4).

Step-by-step instruction

Many craftsmen supplement the “basic assembly,” for example, with a fertilizer dispenser. This device allows fertilizing to be carried out simultaneously with planting.

Let's take a closer look at the process of assembling a planter for a walk-behind tractor and a mini tractor.

For walk-behind tractor

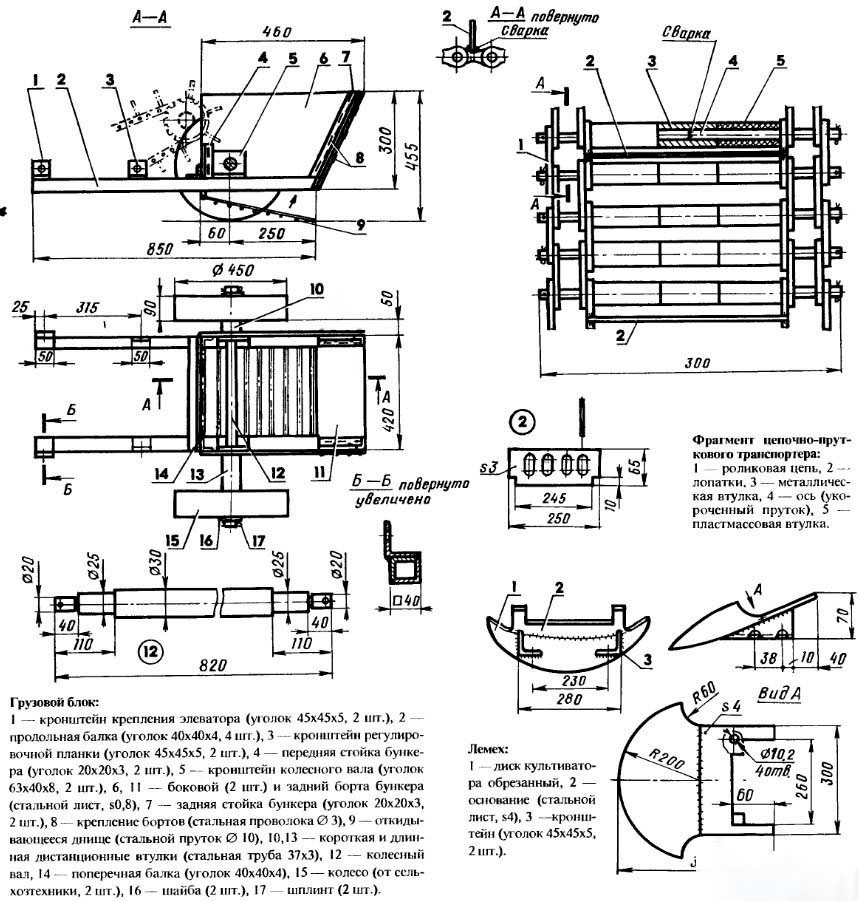

First, the frame is made. To do this, use a channel (steel size 8). Longitudinal spars with three cross members are attached to the frame.

Sheet steel is usually used for the bunker, but 10 mm thick plywood is also suitable for small equipment. This will be enough for 20 kg of potatoes.

An elevator is installed in the bunker, which is secured in a vertical position. Bowls with a diameter of 5-8 cm are placed on it. For everything to work, the mechanism is connected through a chain drive to the drive wheel. To remove the tubers, the seed tube is fixed under the elevator.

A sprocket (8 cm) is connected via a chain to the walk-behind tractor to transmit force. This element transmits the movement to the digging discs.

This design allows you to use a regular bicycle chain. The distance between tubers will be 35 cm.

Important! After the main installation, the frame must be strengthened with steel strips. The arch also needs reinforcement. For this purpose, sheet steel plates are used.

For mini tractor

The diagram of such a unit is shown in the photo:

Algorithm of actions:

- Manufacturing begins with a frame on which the remaining elements will be placed. To do this, longitudinal spars are welded from channels. They are connected to each other by steel strips.

- An arch with forks directed towards the central rod is welded at the front.

- The frame is reinforced with steel beams. They are fixed on the other side and to the middle of the arch.

- A seatpost support is made from the corner and mounted on the spar.

- A bracket on which the bunker will be placed is welded to the inclined beams.

- The potato tank is welded from sheet steel 2 mm thick.

- The hopper is secured to the bracket with bolts.

- Now the ripper and wheel axle are mounted to the bottom of the frame. For the axle, an ordinary steel pipe is used as a base, at the ends of which axles are placed. For the wheelbase, you can take wheels from old equipment.

- Ripper holders are made in the form of squares made from rods. Clips with a steel thickness of 6 mm are welded at the ends. They will house cultivator stands.

- The seeder is made from a steel pipe with a cross-section of 100 mm. The minimum wall thickness should be 3 mm.

- A furrow cutter is welded to the bottom of this pipe. The thickness of the steel is at least 6 mm.

Tips and tricks

The landing process using such a device is as follows:

- Place another 2-3 bags of potatoes on top of the filled tank to save time when the tank is empty.

- One person should be on the potato planter, and the second on a walk-behind tractor or mini tractor.

- Do not exceed the speed of 1 km/h.

- It is desirable that the design of the device include discs that bury the holes.

- To change the planting depth, adjust the stepladders or change the angle of the discs.

Conclusion

Making a potato planter yourself is a complex but doable process. If you prepare the drawings in advance and follow the instructions, any home craftsman will succeed. Even a small device like this will save a lot of time and effort.