How to ferment tobacco at home: the best ways

Homemade tobacco is a real pleasure for connoisseurs. Unlike industrial, it has a more aromatic smell and pleasant taste. It is safer because it is not treated with chemicals.

But growing and drying tobacco is only part of the harvesting process. To obtain a soft taste and reveal the aroma, tobacco is fermented. In this article we will figure out how to ferment tobacco at home.

What is fermentation

To obtain aromatic tobacco with a pleasant taste and the required strength, simple is not enough dry tobacco leaves. Aromatic substances and nicotine are contained in the vacuoles of plant cells - special organelles with dense membranes. Also, dried raw materials contain pectins, proteins and starchy substances, the destruction of which increases the astringency and aroma of tobacco.

To destroy storage substances and vacuole shells, it is necessary to activate the lysis of chemicals with the help of cell enzymes. The activation of cellular enzyme systems that trigger the breakdown of carbohydrates and proteins followed by the release of nicotine from the vacuoles is called the fermentation process.

Reference. The Kentucky Barley and Jubilee New 142 tobacco varieties do not require fermentation; they are used immediately after drying.

Fermented tobacco leaves dark brown without green. The herbaceous smell is replaced by an aromatic tobacco one, characteristic tart notes appear, and the taste of tobacco is revealed. Tobacco smoke after fermentation becomes less pungent, bitterness decreases, the tobacco itself smolders better and does not go out when burned.

Conditions for activation of tobacco enzymes

Plant enzymes are complex proteins that activate chemical intracellular processes. Enzymes are biological catalysts; they accelerate the natural processes of oxidation, destruction or synthesis hundreds of times.

Any biochemical processes require water as a medium for reactions to take place.. Fermentation takes place at a humidity of 60-70%, for which the dried raw materials are sprayed from a spray bottle and covered with waterproof material to maintain moisture levels. At this stage, you can flavor tobacco by dissolving essential oils, cognac or honey in water.

The higher the cell temperature, the more active the enzymes, but temperatures above +50°C can destroy the biological catalysts themselves, so a constant temperature of +45-50°C should be maintained. It must be kept for up to ten days for fermentation to take place completely.

Temperature and humidity can do more than just ferment tobacco, but also become favorable conditions for the growth of mold on tobacco raw materials, therefore another condition for proper fermentation is the sterility of objects touching the tobacco.

Fermented tobacco is slightly dried so that the leaves remain flexible and do not break at a break, but are dry to the touch. This tobacco can be used immediately or stored.

Preparation of raw tobacco for fermentation

Dry leaves can be separated from the veins and cut before the fermentation procedure, but this procedure is optional.The veins and stems of tobacco are sometimes not thrown away, but are crushed and used for agricultural purposes to protect against insect pests. Tobacco decoction and infusion, which is sprinkled on fruit crops, is an environmentally friendly insecticide.

Sheet raw materials are sprayed with water at the rate of 1 spray per 1 sheet. After this, the tobacco is covered with a damp cloth for 2-4 hours. When the leaves become tight and stop breaking when deformed, they are placed in a bag or a clean glass jar. Drops from wet leaves are removed with a dry towel.

If, when heated to +50°C, condensation forms on the walls of the bag or jar, the raw tobacco is slightly dried and put back into fermentation. Before storing raw materials, bags or glass jars should be disinfected with alcohol or vodka to prevent the tobacco from becoming moldy.

Fermentation methods at home

Fermenting tobacco at home does not require special equipment. Constant heating is provided at home using household heating appliances.

Stove

To the happy owners of a Russian stove it is enough to place containers with moist tobacco covered with a cloth on the ceiling or bench and turn on the stove once every two days. Stone and clay retain heat for a long time, which allows you to get aromatic fermented tobacco in 7-10 days.

Heating battery

During the heating season, central heating radiators or heaters are used. Their temperature is slightly higher than that required for fermentation, so containers with tobacco are covered with a jacket or towelto prevent overheating and destruction of tobacco enzymes. This fermentation can last up to 30 days.

Reference. The longer the tobacco is aged during fermentation, the more aromatic and smoother the smoke will be.

Oven

An oven with a temperature controller is suitable. It is preferable to use an electric oven. In this case, the tobacco is fermented in jars; the bags will melt upon contact with the walls and grates of the cabinet. It is enough to turn on the oven once a day for 8-10 hours at a set temperature of +50°C and the cabinet door closed. In 6-7 days the tobacco will be ready.

Multicooker

The tobacco is rolled up and placed in a fabric bag.. They are placed in layers in the multicooker container and the temperature is set to +45-50°C. The steam release valve is covered with foil to prevent moisture from evaporating. The layers of tobacco are mixed 2-3 times a day so that the heating is uniform. After 3-4 days, the tobacco is ready for use.

Microwave

One of the fastest fermentation methods. The prepared leaves are cut into strips of 2 mm and placed in glass jars. Next, they are covered on top with a glass lid or saucer to prevent moisture from evaporating. The microwave panel sets the minimum power.

Heating is continued for 30 minutes, after which the jars are cooled. The heating process is repeated 3-4 times until the desired aroma. In general, the process will take 5-6 hours. To prevent the tobacco from burning, stir it in the intervals between heating.

Water bath

The jar with the prepared leaves is placed in a hot water bath with the lid closed.. At the same time, monitor the temperature of the water in the bath - it should not exceed +60°C. This fermentation lasts 4.5-6 hours.

other methods

Fermentation can occur naturally without the use of equipment. These methods were used when tobacco could only be prepared using solar heat, even before technological progress burst into people's lives.

The first ancient method of fermentation can be carried out in summer in sunny, dry weather. Cans of moistened tobacco are buried 30 cm deep in the ground.. The soil heated by the sun maintains a constant fermentation temperature, and in 3-4 days the tobacco will be ready.

Second way - jars with prepared tobacco raw materials are taken out into the sun and placed on a metal tray or dark stone that heats up naturally. Since the jars cool overnight, this fermentation can last 10-15 days.

Cooking tobacco in a fermentation oven

Best quality The fermentation process takes place in a special fermentation cabinet.

Best quality The fermentation process takes place in a special fermentation cabinet.

Pros of using it:

- tobacco does not absorb foreign odors and does not itself aromatize the room or household appliances;

- fermentation occurs evenly along the entire length of the tobacco leaves;

- the process proceeds relatively quickly - from three to six days;

- minimal effort and time to control fermentation;

- Large volumes of tobacco can be fermented at one time.

Such It’s easy to make a cabinet with your own hands from scrap materials. You can also purchase a ready-made fermenter.

It can be useful:

Varieties and characteristics of tobacco varieties

Making a fermentation cabinet

If you don’t want to purchase a ready-made unit, we offer you instructions on how to make a fermenter with your own hands. There are two main requirements for fermentation cabinets: fire safety and low energy consumption.

Materials for making a cabinet:

- Metal box and wooden boards. The metal frame can be welded independently from tin sheets; the volume of the box is selected based on the expected volume of tobacco. The top of the metal structure is covered with wood with fire-resistant impregnation to save energy on heat transfer. If metal welding and carpentry aren't your thing, you can use an old refrigerator, a metal safe, or an old oven. The main thing is that the design has a door, a metal bottom for attaching heating elements and does not have plastic elements inside.

- A heating element. Thermal elements of electric stoves, air heating elements, infrared lamps or heat guns are used as such devices. The main requirement is the presence of a temperature controller. One of the most energy-saving options is infrared lamps. They provide soft, even heat and can be used in rooms without heating. Such lamps are sold in hardware and veterinary stores (they are also used for bird incubators).

- Controller and components. This fermentation oven component automatically turns the heating element on and off so that the oven remains at a constant temperature regardless of external conditions. If you don’t want to tinker with electrics, use a heating element with a regulator - for example, the regulator elements of an electric stove. But in this case, you will have to periodically check the temperature in the cabinet and independently adjust the level of power supplied to the heating element, turn the heater on or off if necessary.

- Electrical wires with protection, switch, plug for connecting to the mains.

- Metal gratings.

- Fireproof impregnations or liquid glass, screws, nails, door handles and other small consumables.

Materials and components can be purchased at construction and hardware stores.

Stages of making a cabinet:

- Sheets of metal sheet of the required size and corner metal profiles of the required length are cut out. The structural elements are welded together. Metal corners are welded inside the cabinet for subsequent fastening of metal grilles.

- Wooden boards are cut to the size of the cabinet and treated with fire-resistant impregnation. After it dries, the cabinet is covered with them on the outside along the perimeter, the joints in the corners are covered with an angular metal profile. The boards are attached to the door using U-shaped metal profiles.

- The door is attached to the cabinet using metal hinges. A heat-resistant rubber seal can be attached around the perimeter of the door.

- A lock is attached to the cabinet wall and door (a regular hook and eye will do).

- Wooden or metal legs are attached to the base of the cabinet with self-tapping screws. It is better not to use plastic if the heating element is attached to the bottom of the cabinet, as the bottom will heat up.

- The heat elements are attached to the base of the cabinet. If infrared lamps are used, they are attached to the cabinet walls so that each shelf is illuminated by one lamp. The necessary holes for wiring are drilled.

- The controller and components, regulators and sensors are attached. Wires are being laid. To prevent them from overheating, they are placed outside the box.

- Metal grilles and door handles are installed. If desired, the outside of the box is coated with radiator paint.

If you used the case from an old refrigerator, it is enough to install the heating element, controller, wiring and dismantle the internal plastic elements.

The cabinet can be installed in any room protected from rain. In addition to tobacco fermentation, this design is suitable for tea fermentation, drying herbs, mushrooms and berries.

Fermentation technique in a fermentation cabinet

Moistened prepared tobacco is placed in glass jars and tightly closed with a lid so that the moisture does not evaporate. The temperature is set on the regulator to +50°C, the tobacco is placed on the cabinet shelves.

During fermentation, the cabinet operates 24 hours a day. If there is no temperature sensor inside or the cabinet is not equipped with a controller, the temperature inside is measured once a day and the heat supply is adjusted if necessary. After 3-6 days, the tobacco is ready for use.

Read also:

Recommendations for making fermented tobacco

When carrying out fermentation, it is worth considering a number of subtletiesto control the process and correct errors or weed out defects in a timely manner.

Tips for getting a quality product:

- Fermented tobacco has a rich brown color and a specific tobacco aroma. Green leaves or leaves with the smell of burning, rot or mold should be thrown away; the listed signs indicate spoilage of the raw materials.

- When carrying out long-term fermentation, after 2-3 days the leaves begin to exude honey notes in the aroma. If they are not present, this indicates insufficient or excessive fermentation temperature; the heat supply should be adjusted.

- During fermentation, condensation should not accumulate in jars or bags.If liquid droplets form on the walls of the container, the tobacco is over-moistened. The leaves should be dried immediately and the container should be wiped dry with a towel before refilling the raw materials, otherwise the supplies will smear or become moldy.

- After fermentation, you can let the tobacco rest for 1-2 days so that the leaves become more aromatic and stronger.

The fermentation process does not stop once it has started., so the longer the tobacco is stored before use, the more aromatic it will become.

Conclusion

Fermentation is a complex biochemical process that produces more aromatic and rich tobacco.

It can be carried out in the sun and at home, using radiators, an oven, a microwave oven, a water bath or a slow cooker. The highest quality tobacco is prepared in a special fermentation cabinet, which you can make yourself. After fermentation, tobacco acquires a characteristic aroma, taste and golden brown color.

Thanks for the advice!

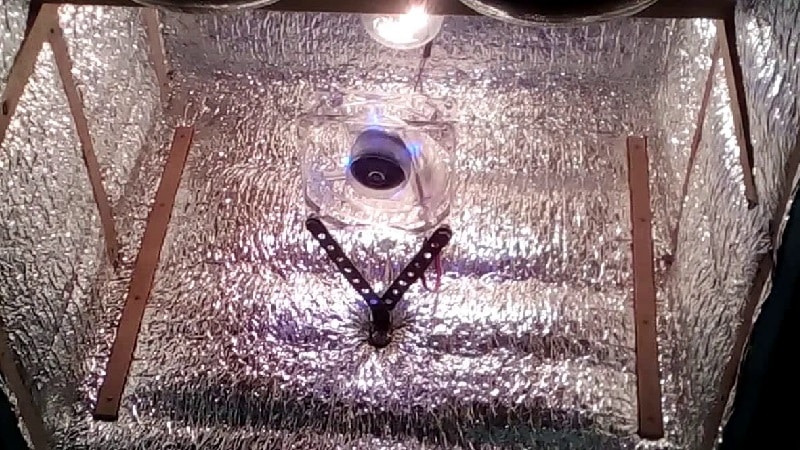

The fermenter is simply made from a cardboard box lined on the inside with foil insulation, a digital thermostat with a temperature sensor - 180 rubles. on Ali Express (yesterday I took a second one, in reserve)! Fermentation - 14 days at a temperature of 47 - 50 degrees, for oriental varieties - 20 days at a temperature of 40 degrees, just like that and not otherwise! Heeh😂, but in 3-6 days as you recommend, you definitely won’t succeed!