How to make a potato hiller for a walk-behind tractor with your own hands

Hilling up agricultural crops preserves soil fertility, increases cultivation efficiency, and reduces the cost of fertilizers and watering. It is impossible to harvest a rich harvest of some vegetable plants, especially potatoes, without this procedure. But manual hilling is long and tedious. It is faster and more economical to use a walk-behind tractor with a hiller. You can make such a device yourself. Let's look at what types of potato hillers are available for a walk-behind tractor and how to make them with your own hands.

What is a hiller for a walk-behind tractor: description and characteristics of the device

Hiller is a mechanism by which soil of varying extent and complexity is plowed and cultivated.

The nozzle is used to cultivate agricultural crops, loosen, dig up soil, and fight weeds. The device is made of metal, has blades or is equipped with rotating disks that are attached to a frame.

Install the attachment on the walk-behind tractor using special fasteners. Attachments provides different hilling heights and depths of penetration into the ground. Along with loosening, the device lifts the soil to the required level and aerates it. The width of the boning, height and angle of inclination depend on the model.

What types of hillers are there?

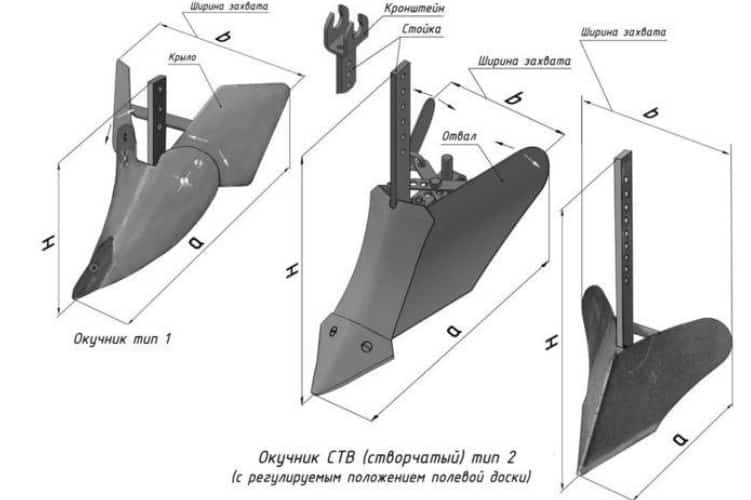

Depending on the design features of the nozzle for hilling are divided into several types.

Listerny

Externally it resembles the wings of a butterfly.Features a fixed working width. Due to the sharp ends, it sinks to the set depth.

Advantages of the mechanism:

- simplicity of design;

- low energy intensity;

- light weight - does not require powerful units;

- the price is lower compared to other types of hillers.

Plant potatoes It is important to do it evenly, strictly observing the same row spacing. The device does not cope well with wet and heavy soil.

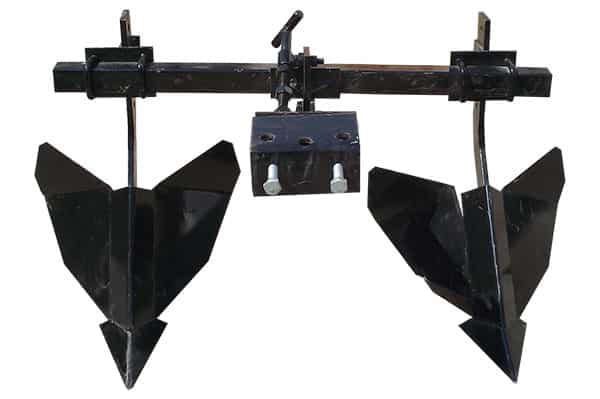

Twin

This is a double-row or swing mechanism for cutting even parallel furrows over large areas and hilling them up. The height of the ridge varies from 10 to 20 cm and is limited by the rise of the gearbox relative to the soil level.

Advantages of the unit:

- versatility of use;

- ease of building even furrows over large areas;

- adjustable distance between plowshares;

- the ability to make ridges simultaneously on both sides of the planting.

The nozzle requires regular cleaning and treatment with an anti-corrosion compound. The device is designed for light, pre-prepared soils.

Dutch

The design of the potato hiller allows the blades to rotate in horizontal and vertical planes. The lower edge of the wings resembles a comb.

Advantages of the mechanism:

- improving the quality of work;

- use of low-power walk-behind tractors;

- profitability (the device has a low price).

The nozzle functions in tandem with a car weighing from 30 kg, recommended for use on any type of soil.

plow-shaped

This is a streamlined mechanism. Its advantages:

- low intensity of soil inversion;

- preservation of moisture in the soil due to less aeration;

- ease of tilt angle adjustment;

- processing a large area.

Using this model, farmers reduce the time and effort spent on cultivation. It is better to use a plow-shaped attachment with a powerful walk-behind tractor.

Disk

The working elements of the hiller are circles that penetrate the soil to an adjusted depth.

The mechanism is popular for the following reasons:

- high reliability and durability;

- ease of use;

- compatibility with all types of cultivators and increasing their power;

- Convenience of rolling down root crops.

The attachment is mainly used for processing potato plantings.

Information! The angles of the disks must clearly correspond to each other, otherwise the unit will move away from the desired direction.

Propeller

Mechanisms of this type are also called active, or rotary, and are similar to fan blades. The operating principle involves 2 rotational forces and translational movement.

Positive aspects of the unit:

- the nozzle not only hills the plants, but also transfers the soil from place to place;

- the device effectively fights weeds;

- the beds are covered with loosened soil - the growth of plantings improves.

The model is not compatible with all types of cultivators. Use the propeller attachment only on walk-behind tractors with two forward gears.

How to make a potato hiller with your own hands

It is important to adhere to the rules and strictly follow the installation instructions. Drawings and dimensions must be accurate.

To make a nozzle yourself, you will need:

- select a suitable drawing;

- select equipment;

- study the sequence of actions.

It is strictly necessary to observe dimensions and symmetry, otherwise deviations from the norm will affect the operation of the unit.

Tools and materials

Before starting work, prepare the equipment and necessary materials:

- arc welding machine;

- bolts, fasteners;

- grinder with discs and attachments;

- files of different sizes;

- electric drills with drill bits;

- Workbench;

- emery operating from the network;

- gas burner.

To create a nozzle, durable metal is required, preferably high-alloy steel. The material is resistant to mechanical stress and rust.

Constructing a lister hiller

Making a mechanism is not difficult. Step-by-step instruction:

- Take a strong metal sheet 3 mm thick. Cut a blank from it according to the drawing.

- Sharpen on the side where the bottom edge will be.

- Bend in the middle through the secured pipe. Punch through the front edge with a hammer.

- Extend the wings of the nozzle.

- Use a cross member to fix the distance between the blades by welding it at the back of the planes.

- Punch through the bottom of the part so that the blades are plowshare-like.

- At the front of the hiller, weld a stand with holes.

- Bolt the rod going to the walk-behind tractor to the stand.

If an adjustable attachment is required, the wings are secured using hinges and a rod.

Twin

Instructions for creating the design:

- Cut or saw out a strip of 2 mm thick iron sheet.

- Form rectangular slits on each side.

- Bend the fabric in the middle so that it goes around the back of the square bar at a 90° angle, forming a front double eye.

- Thread the attachment stand into it.

- Drill a hole in the mount for the bolt.

- Make holes on the left and right sides of the rod cavity with the same distance between them.

- Carve by hand. Use a tap and wrench.

- At the back of the fastening, through the thread in the rod, tighten the bolt until it stops.

- Weld a stand in the middle part of the crossbar to ensure reliable coupling of the attachment to the walk-behind tractor.

By moving the structure along the rod, the width of the rows is adjusted and double twisting is carried out. The blade mode is set by extending the wings. For proper operation of the mechanism, special attention is paid to the quality of fastening of the stand in the eye.

plow-shaped

Step-by-step creation of the mechanism:

- Make a frame. Take an iron pipe measuring 52x40 mm with a wall thickness of about 7 mm. Cut off the opposite partitions and make a fork.

- Mark the middle on the frame. Weld the hole in the front part of the frame structure.

- Secure the plow stand. In a wide piece of pipe, drill through holes with an area of 3.1x1.6 cm for the supporting part. Make the size of the holes in the narrow walls of the frame no more than 1.02 cm.

- Make a handle from half-inch diameter pipe.

- Design a hitch. Use a channel mount in the shape of a “P” and install it under the steering part.

- For the main working parts, take a metal sheet up to 5 mm thick. First make a ploughshare. An old circular saw blade will work for this. Use an anvil for sharpening.

- Create a dump from a pipe 0.6 m long. To do this, take cardboard or paper as a template, attach it to the pipe, and trace it. Cut with a welding machine. Sand with sandpaper or grinder.

- Assemble the plow. Weld the parts to a steel sheet with an area of 0.25 m². Using a hammer or chisel, remove the base on which the preparatory work was carried out.

- Clean the seams, sand the blade and plowshare.

Paint the finished structure.

Important! Compliance with dimensional accuracy is mandatory.

Dutch

To make a nozzle, follow the following sequence of actions:

- Cut the wings from a 3 mm sheet of iron.

- Sharpen the edge under the bottom edge.

- Fold in the middle.

- Beat off the front edge with a hammer.

- Spread the blades of the nozzle.

- Weld the cross member behind the wings, adjusting the distance between them.

- Punch through the bottom of the part and make it look like a plowshare.

- Secure the stand with holes by welding to the front part of the hiller.

- Bolt the rod that goes to the walk-behind tractor to the stand.

- Adjust the attachment by attaching the wings to the hinges of the rod.

The device is ready for use.

Disc manual hiller for potatoes

The mechanism consists of 2 circles with a hub, a cross beam, a handle and racks. Step-by-step production:

- Take a steel sheet 3 mm thick. As an alternative, use lids from 50–60 cm pots or discs from an old seeder.

- Cut out circles with a diameter of 45–50 cm.

- Sharpen the edges at an angle of 45° using a machine or grinder.

- Weld the hubs in the center.

- Make the mounting brackets from pipes measuring 32x45 and 45x55 mm. In the middle of the longer pipe, secure the shorter one by welding. Drill a 12 mm hole in a pipe with a diameter of 45 mm. Weld the nut so that the bolt is screwed in completely.

- Make a stand. Bend 2 jumpers from 32x250 mm pipes at an angle of 30°. Fit the 45x55 mm bushings by butt welding from one edge, and from the opposite - perpendicular to the end. Make holes with a drill and weld nuts to them.

- Assemble the handle from thin pipes and a 45x120 mm sleeve, in which 12 mm holes are made.

- Carry out general assembly. Paint metal surfaces. Insert the cross beam into the handle sleeve and secure with locking bolts. Secure the disc hubs to the racks. Screw the bolts so that they fit into the holes in the bushing. Place the rods with discs on the cross beam. Screw it in.

- If desired, the fastening of the circles is made adjustable.

In order for the device to function, nicks are removed from the surface of the disks. The curvature must be strictly symmetrical, otherwise the nozzle will not work.

Propeller

A homemade ridge former is used not only for adding soil to potatoes, but also for planting vegetables.

Instructions:

- Prepare a metal sheet with a thickness of 2 mm.

- Cut 3 strips for the axles.

- Make 3 holes at equal distances from each other.

- Create a stand and base. Weld using arc welding.

- Secure one strip in the middle of the base, the other two on the sides. Fit them to the walk-behind tractor.

- Select the distance between the elements, the shape of the lugs, and the angle of the unit.

- Design several bushings with brackets, various sets of blades.

- Attach the hiller to the walk-behind tractor, adjusting the angle of attack and depth of penetration into the ground.

The unit is ready for use.

Tips for use

Even if the stages of making the hiller were followed and everything was done correctly, it is important to learn how to use it, properly configure and sharpen the parts. After assembly, the unit is tested on site. The quality of work will depend on the condition of the soil, climate and weather on the day of plowing.

Adjust the mechanism as follows:

- They walk the nozzle along the ground, set the angle of inclination of the elements and the depth of immersion. It should not exceed the total length of the product.

- The device should not throw soil around and worsen the appearance of the furrow.

It is prohibited to use the equipment if animals and children are nearby. Do not use the machine in a faulty condition or leave it unattended.

Conclusion

Making a hiller for a walk-behind tractor with your own hands is not difficult. It is important to use it wisely.Lister and dual types are suitable for processing light soil. If the walk-behind tractor is low-powered, it is better to use a Dutch or propeller mechanism. On dense, clayey soils there will be more impact from a disc. If all operating recommendations are followed, the unit will last a long time.