Review of the model of mounted potato planter SN 4B

To increase the productivity of planting potatoes, as well as to reduce labor and time costs, farmers use potato planters. Most often, such a unit is an attachment (module) that is mounted on the base of a manually controlled walk-behind tractor. More productive models of potato planters are pulled along the furrow using tractors. The article will tell you about one of the varieties of such equipment - the SN-4B potato planter.

What kind of unit is this

Semi-automatic potato planter CH-4B is used for smooth row and ridge planting of potatoes, unless they have previously been germinated. At the same time, mineral fertilizers are automatically applied into the furrow under the tubers.

Planting is done in beds with a distance between ridges of 60 and 70 cm. The distance between tubers in a row can vary from 20 to 40 cm.

The planter can be aggregated with both walk-behind tractors and wheeled tractors MTZ-80, MTZ-82, as well as tracked tractors T-4A, DT-75N.

In this case, the drive of the potato planter chain is carried out from the rear PTO (power take-off shaft) of the tractor. Such equipment is already intended for large-scale potato production.

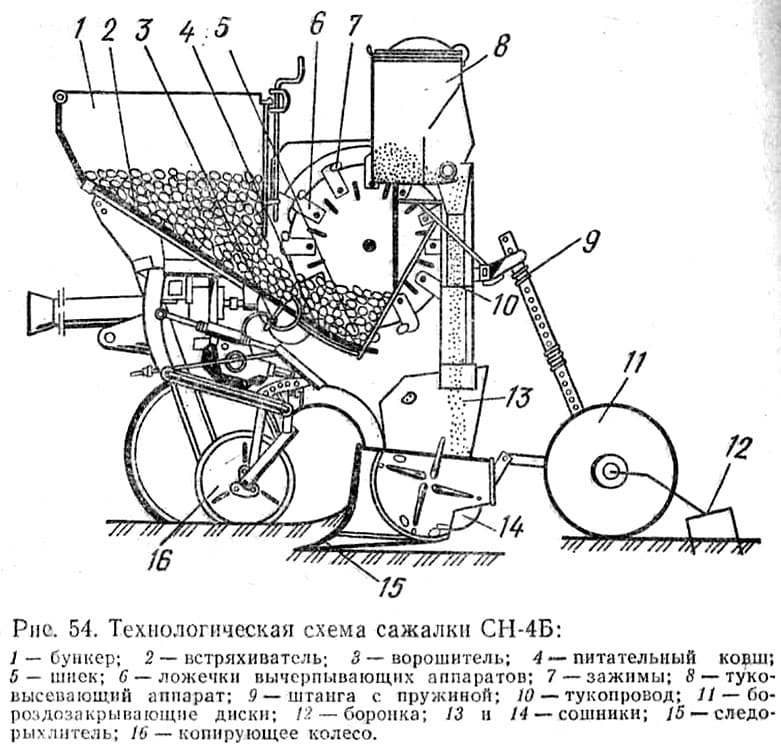

Here is a detailed diagram of the device in question:

The operation scheme of the potato planter can be described as follows. The unit moves along the furrow following the tractor pulling it.From the tractor power take-off shaft, the torque is transmitted to the planter’s feeding bucket: the spoons of the scooping apparatus engage the tubers and sow them into the furrow at regular intervals.

In addition, immediately before sowing potatoes, bulk fertilizers (usually mineral) are applied into the furrow through a fertilizer pipe. After this, the potatoes are covered with soil from neighboring ridges using the planter coulters.

Reference. The potato planter has a seed tuber hopper with sufficient capacity to sow from 59 to 71 thousand tubers per hectare.

Specifications

The SN-4B potato planter has the following components that provide it with the specified productivity.

Gearbox

Torque is transmitted to the working parts of the planter from the PTO of the pulling tractor through a gearbox, which has two bevel gears with a number of teeth z=40 and z=14. The driven shaft of the gearbox, through replaceable sprockets with the number of teeth z=22, z=20, z=18 and z=16, as well as a chain transmission, transmits torque to the sprockets of the counter-drive shaft (two pieces: with the number of teeth z=22 and z= 40) and then onto the shaft of the planting devices.

In this case, the sprocket z=22 drives the working parts of the potato planter, in fact, from the PTO, and the sprocket z=40 serves to transmit the torque of the working bodies from an independent PTO. The driven sprocket z=12 of the counter-drive transmits torque to the sprocket z=36 of the right and left shafts of the scooping devices.

Wheels

In the design of the SN-4B potato planter, the wheels serve solely to support and move the unit following the pulling tractor (they are connected to the front frame rail).

Unlike some other models the wheels of the unit in question are not connected in any way to the control mechanisms planters and do not affect the speed and spacing of tubers. Also, the support wheels are equipped with a mechanism for raising and lowering the potato planter for more efficient operation.

Bunker

Seed material is loaded into the hopper. It is a box welded from thin sheet steel. Its bottom is inclined towards the feeding ladle, it is also equipped with shakers (flaps). In this case, the rear wall of the bunker is made with a window, which is regulated by a damper.

Feeding bucket

The bucket is an integral part of the bunker, which is designed to ensure uninterrupted operation of potato planting devices. The back of the ladle bottom is curved for free release of scooping spoons. In this case, the side walls of the bucket are rigidly connected to the hopper - they fit into the gaps between the scooping spoons and the disk.

There is a corner divider in the middle part of the bottom – it separates the tubers into left and right flow. And for uninterrupted supply of potatoes to the spoons, augers and turners are provided.

As for fertilizers, they are applied by so-called fertilizer sowing devices - through fertilizer pipes and channels. After the substances are in the furrows, special discs cover them with a layer of soil no more than 10 mm thick. And then the tubers lie on this layer of soil.

Operating rules

To configure the operation of the SN-4B potato planter, the operating speed is initially selected. This is done according to the corresponding table of standards.

Eg:

- when working with a pulling tractor MTZ-80 in second gear, providing a speed of 6 to 7 km/h, and also with the sprocket z=20 installed, from 59 to 71 thousand tubers are planted per 1 hectare;

- when working with an asterisk z=18, the number of tubers ranges from 42 to 47 thousand;

- when working with an asterisk z=16, the number of tubers ranges from 35 to 41 thousand.

The PTO ensures that the drive performance depends on the speed of rotation of the axles of the tractor's drive wheels. Therefore, the distance between the sown tubers does not depend on the speed of the potato planter. The PTO makes 3.5 revolutions per linear meter of the unit’s trajectory. However, an undesigned, that is, too high speed of movement of equipment increases the risk of missed areas for planting tubers and their damage. High planting speed is harmful to seed material.

A replacement sprocket is selected based on trial runs. To do this, it is necessary that the potato planter travels at least 8-10 m. If the distance between the ridges of the rows is 70 cm, count the number of planted tubers over a length of 7.14 m. In area this will be 5 square meters. m. Next, the resulting amount is multiplied by 2000 - this will be the number of potatoes required for sowing per hectare. If the obtained value does not fall within the standard range, then the sprocket on the gearbox shaft is replaced.

Important. The potato planter must move at the designed speed.

Where to buy and how much it costs

Semi-automatic potato planters SN-4B are widely used in medium-sized agricultural enterprises. Plus, their models with various improvements are manufactured by many agricultural engineering factories. You can purchase such planters either new or used.

Their prices are in the range:

- new ones - from 220 to 420 thousand rubles;

- used – from 40 to 180 thousand rubles.

Advantages and disadvantages

Let's start with the advantages:

- SN-4B has a very laconic design, which compares favorably with complex imported units that are similar in functionality. This means relative ease of installation and availability of spare parts.

- The potato planters under consideration are lightweight (no more than 1.1 tons without loading), which ensures low specific pressure on the ground.

- Potato planters SN-4B provide high productivity, as they are able to work at the second speed of the tractor (up to 7 km/h).

- Affordable (compared to imported analogues) price.

However, there are also disadvantages:

- Low reliability of the design, which entails frequent failure of components and parts.

- The main material for the manufacture of the potato planters under consideration is carbon and alloy steel (not stainless steel), as a result of which the unit is subject to intense corrosion when stored in an unheated room.

User reviews

The most objective characteristics of the quality of the SN-4B potato planter are provided by its users. Let's evaluate some of them:

Victor, Balakovo: "If you have a YuMZ, MTZ 50, 80 and higher tractor, then you can use it... It doesn’t like heavy soils - it “lifts” it on them. It does not like clogged soil - the coulter gets clogged and the support wheel jams. Small bunker - needs to be expanded. If the paddock is short, you can work; if it’s long, then you have to reboot. And since the potato planter is quite heavy, it is advisable to improve the ratio of weight and useful loading of the bunkers by modifying the model yourself.”

Evgeny, Tambov: “There are practically no skips if the springs on the pressure fingers are normal. He doesn’t really like cut potatoes, but if the potatoes are sprouted with eyes up to 0.7 cm, then they plant better. If the sprouted one is larger, it breaks the sprouts.”

Denis, Volzhsk: “Four tons per 1 hectare at the third slow speed - the sowing distance will be approximately 15 cm, the seed size will be the size of a chicken egg. A trifle in the second direct drive, and accordingly, the consumption is higher. Another point: keep the speed in the range of 1500-1700, with a dependent PTO of 540; if it’s faster, there will be misfires. The seeding rate can be adjusted not by removing the “feet”, but simply by inserting another gear. When we bought the planter, we immediately calibrated it, in which gear to plant how much, and the plantings also need some finishing touches.”

This is interesting:

How to make a potato planter for a mini tractor with your own hands.

Step-by-step instructions for creating a homemade potato planter.

Summary

The potato planter SN-4B is a productive agricultural unit, quite technologically advanced and in terms of complexity fully consistent with its purpose.

It is easy to calibrate, adjust and repair, which is extremely important for field conditions. But the main advantage is the performance indicator of the SN-4B in relation to its cost. According to the latter parameter, similar equipment produced in the territory of the former Soviet Union still remains uncompetitive, mainly due to its low price.

Thank you. Your article helped

Hello, I was looking for 2 characteristics for 2 different potato planters, your site was very helpful, in addition to the simple design, there were also advantages and disadvantages, this is simply the best that could be found, thank you very much