How to make buckwheat for porridge

Buckwheat, which is familiar to many, has several varieties: core, seka, Smolensk, flakes. Each fraction, before reaching the buyer’s counter, goes through a number of production stages: sorting, frying, crushing, sifting. Let's look at what and how exactly buckwheat porridge is made from.

What is buckwheat made from?

Grains buckwheat obtained from the herbaceous honey plant buckwheat. After ripening, the fruits are sent for processing. In agro-industrial production, the collected raw materials are first passed through a stone removal machine, which sifts out debris: small stones, plant branches.

Further processing is carried out in 2 directions:

- To obtain steamed buckwheat, the grain is sent to a special tank for 1 hour. Under pressure of 3 atmospheres and at a temperature of +130°C, the raw materials are fried. As a result, it turns brown and the husk separates well.

- Processing without thermal process. The grain is pre-cleaned from husks by rubberized rollers. The output is green raw material.

The steamed grain is sent to a workshop where peeling and separation are performed. The husk is separated by blowing.

The exfoliated product goes through 4 stages of calibration on special vibrating tables with cells of different diameters. As a result, 8 fractions are obtained, differing in the integrity of the core. This is how buckwheat, which is familiar to many, is made.

Interesting! In 1968–1975On the basis of the VNIEKIprodmash Research Institute, a technology for sorting grain without heat treatment was developed.

The essence of the method is that on tables with rubberized rollers and sorting cells, grains are separated in several stages without the use of steam. First, the purified ones are sorted from the unhulled ones, then the coarse and finely ground fractions are sorted. This allows you to get more whole grains at the output, and the manufacturer can reduce costs and increase the productivity of the technological process.

What types of buckwheat exist?

Depending on the degree of grinding and integrity of the grain, several types of buckwheat cereals are distinguished.

Yadritsa

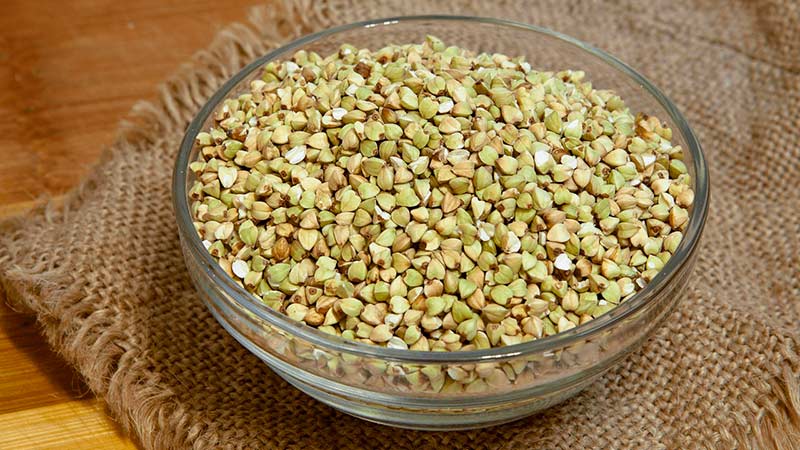

Primary sorting of the harvested crop and separation from the husks with minimal mechanical processing makes it possible to obtain whole buckwheat fruits - the kernel. There are green (raw, not heat-treated) and brown, obtained after roasting the grain.

Such raw materials retain the upper nutritional shell and triangular shape. Considered 1st grade.

Prodel, or chop

Buckwheat is popularly called “cut”. It ranks second in popularity among consumers. This is a kernel that has undergone primary crushing, as a result of which it is cut into 2 or more parts. The crushed raw materials are passed through a sieve and separated from the fine grinding fraction.

Important! Prodel partially retains the upper shell, which contains the maximum amount of vitamins, but loses its original triangular shape, and therefore belongs to the 2nd grade of cereal.

Smolensk groats

To obtain this product, the product undergoes additional crushing. The result is finely ground buckwheat, reminiscent of semolina in structure.Flour dust is removed through a fine sieve, and larger particles are sold as Smolensk grits.

Only the middle of the light brown grain remains in its composition. This is the 3rd grade of buckwheat, which is cheaper than the previous ones. It is used to prepare viscous porridge or as an ingredient in baked goods.

Flakes

The flakes retain all the beneficial qualities of buckwheat. There is no need to cook them, since they have already undergone primary roasting. The product is produced not in large industrial plants, but in small-scale enterprises.

There are 2 methods of obtaining buckwheat flakes:

- fried buckwheat grains are cut into thin slices using special machines;

- under a powerful press, the kernels are flattened to obtain thin plates.

The flakes are used for quick and dietary nutrition: just pour boiling water over them and let it brew for a few minutes. The product is easily and quickly absorbed in the body.

Flour

What is buckwheat flour made from: the grain (prodel or small fraction of the kernel) is thoroughly ground to a consistency reminiscent of dust. The product manufacturing technology includes several stages:

- initial purification from impurities;

- crushing and grinding of raw materials;

- sorting;

- quality control.

The output is 1st grade flour, which is used for baking bakery, culinary and confectionery products.

Green buckwheat

Buckwheat grain that has not been roasted or steamed retains its original color - green. The basis of the cereal is the core of the fruit.

Green, uncrushed buckwheat is capable of sprouting and giving life to a new plant. Used as food for dieters, raw foodists and vegetarians.

Read also:

How long can buckwheat be stored at home?

What is the largest variety of buckwheat - detailed description

Preparing grains correctly: do you need to wash buckwheat before cooking and how to do it

Conclusion

Buckwheat groats are made from the fruits of buckwheat, a herbaceous plant of the Buckwheat family. Industrial grain processing technology makes it possible to obtain several food products at once: kernels, flakes, prodel, flour, Smolensk cereals. Porridges and healthy teas are made from unroasted raw materials.