Review of the industrial model of potato peeler MOK 300m

The auxiliary workers in an industrial kitchen, who peel potatoes almost around the clock, can easily be replaced by the MOK-300M potato peeling machine. This tuber peeler is suitable for use in food service establishments.

What kind of unit is this

General information about the potato peeler:

- Produced by the Belarusian company Torgmash.

- It differs from potato peeling machines of a similar type in its compactness.

- Designed for use in public catering establishments, it facilitates the work of personnel involved in manually peeling potatoes and root crops (carrots, beets).

- Vegetables are peeled in a working chamber that has a built-in mesh and abrasive disc. The peel is removed upon contact with them.

- On tubers, you will have to remove the remaining eyes and peel in large depressions.

To obtain well-peeled potatoes, it is advisable to buy large tubers without eyes. When processing such vegetables, the time for additional checking is reduced significantly.

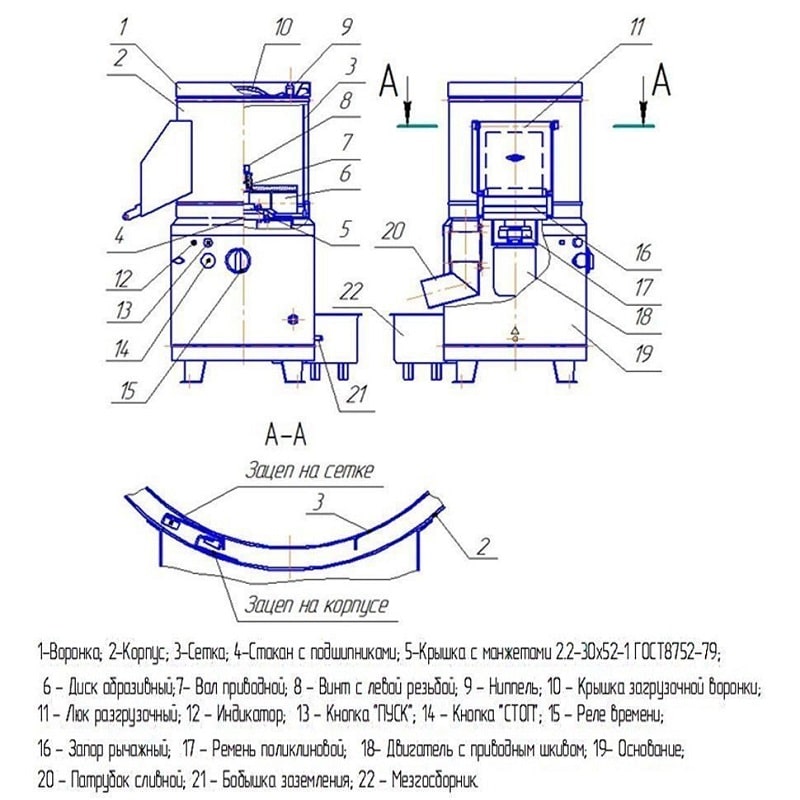

What does it look like

The MOK-300M potato peeling machine resembles a cylinder with a low rectangular base on stands-legs in the form of elongated slats, ensuring stability during operation. The stainless steel housing is designed for floor installation. The potato peeler is used in catering establishments, food production and trade. The working chamber is designed to hold up to 10 kg of potatoes.

Abrasive materials are placed in such a way that potatoes rubbing against them are peeled. The machine's hopper is closed with a special lid for safe operation. After cleaning, the vegetables fall into the receiving tray. Unloading occurs automatically.

Interesting things on the site:

Conveyor potato digger for walk-behind tractor: review of models

Principle of operation

Cleaning is carried out using abrasive materials, which remove the top layer of peel with a rough, heterogeneous surface.

To ensure that the machine works properly, perform the following steps:

- Preliminarily cleared of soil and washed potatoes are placed in the loading funnel, cold water is poured at the rate of 1 liter per 1 kg of product.

- Place the prepared tray into which the potatoes will be automatically unloaded through the door in the hatch after cleaning.

There are “Start” and “Stop” buttons for control. The switch is installed in the network. The device operates from 380 V.

Important! When loading into the bunker, it is advisable to calibrate the vegetables (sort them by size).

The pulp (peel with water) is discharged directly into the sewer or into a container (pulp receptacle), which will have to be purchased additionally, since it is not provided with the potato peeler.

Specifications

The potato peeler is easy to use, does not require special knowledge when caring and is easy to clean. When transported in packaging, it looks compact, which distinguishes it from machines from other manufacturers.

Potato peeling productivity is high: up to 300 kg/hour with a one-time load of up to 10 kg of tubers.

Potatoes loaded into the unit are cleaned within 2 minutes.With a weight of 47 kg, the dimensions are 650 x 450 x 870 mm (length, width, height).

Power consumption - 0.75 kW. The kit includes a mesh and abrasive discs (2 pcs.).

Features of use

To maintain the high performance of the MOK-300M potato peeler in food processing facilities, its technical characteristics are constantly being improved.

Since 2016, the car has appeared in an updated form. They added:

Since 2016, the car has appeared in an updated form. They added:

- a new unloading hatch door;

- improved locking mechanism;

- high-strength abrasive disc made of low-wear material that does not require balancing.

As a result, the degree of potato processing is up to 90% of the peeled surface.

To operate the device you will need:

- three-phase AC network;

- water supply network.

A drainage system is desirable so as not to store the pulp in a working container.

Where is it used?

The MOK-300M potato peeling machine is designed for use in medium and large catering establishments (canteens, restaurants). Manufactured in accordance with the STB ISO 9001-2015 standard and complies with pan-European standards.

Instructions for use

Before using the MOK-300M machine, it is important to read the instructions for its use. To maintain its operation it is useful to know that:

- It is advisable to use cable H05VV5-F5G1 for connecting to the network or similar;

- for safety, the equipment is disconnected from the working network before washing;

- Suitable temperature conditions for operation are +1…+35 °C.

Other operating conditions are listed in the instructions supplied with the unit. It will help you organize its work correctly and become a guide to action if you need to fix minor problems.

Price

The price of a potato peeler in different regions of Russia fluctuates around 44,000 rubles. and higher.

The total price includes delivery costs. It depends on the area, the vehicle and the selected transport company, but can be adjusted if delivery of associated cargo is envisaged.

Read also:

How to make a potato digger with your own hands

Advantages and disadvantages

The main advantages of a potato peeling machine:

- transition from manual labor to mechanized labor;

- high productivity of potato cleaning;

- ease of use.

The disadvantages of an electric potato peeler lie in the quality of the vegetables. Tubers with eyes are not cleaned so well. Loading potatoes of different sizes also has a bad effect on the quality of processing.

Reviews

Those who are faced with the choice of which potato peeling machine to buy for production needs will be interested to know what opinion people have about the MOK 300M brand.

Ivan Sidorovich, farmer: “The potato peeler has served us faithfully since 2014. Helps out during the harvest, when you need to feed an army of workers. I did not observe any significant shortcomings in the work. I’m thinking about buying another unit for a neighboring field camp.”.

Elena Voronenko, head of the factory canteen: “An irreplaceable thing is the MOK 300 potato peeler. It appeared in the kitchen in time when there was a shortage of workers. The workers involved in peeling potatoes are classified as laborers, and staff turnover is unpredictable, but now we work without rush jobs. It would be nice not to use manual labor at all, but the eyes require manual removal.”.

Vadim Stalinov, restaurateur: “I constantly use new technologies.I'm happy with the potato peeler. The advantages include a convenient loading hatch and automatic unloading. I can only judge the negative aspects (it does not cope well with the eyes of potatoes when peeling them) superficially. Sometimes it happens, but more often we buy large potatoes, which we don’t even have to peel.”.

Conclusion

The MOK 300M potato peeler is popular in catering establishments. This invention has proven its effective use: peeling 10 kg of potatoes in 2 minutes, the unit can cope with 300 kg of vegetables in an hour. It would take about 50 people to process this amount of potatoes in the same amount of time.

With such a ratio of the results of manual and machine labor, the machine is a priority. The costs of its acquisition pay off quickly.