Conveyor potato digger for walk-behind tractor: review of the best models and instructions on how to make it yourself

Quick harvesting is important not only for owners of large farms, but also for owners of ordinary household plots. Digging potatoes in 1-2 days is especially important in bad, rainy weather, when it is difficult to find a good day for work. To speed up the process, they use one of the most effective designs - a conveyor potato digger for mini tractor.

What is a potato digger and what is it for?

During harvesting, large agricultural enterprises use serious agricultural technology. In small farms, a walk-behind tractor is most often used, to which trailed or mounted equipment is connected.

The potato digger has a simple device, but can significantly speed up and facilitate harvesting.

Device Description

A potato digger for walk-behind tractors is an attachment that is designed for harvesting. The device is fixed directly to the machine or using a hitch.

The teeth of a potato digger go deep into the ground, extracting potatoes from it, which are then collected by hand.

What is it for?

If we compare the use of a digger with a completely manual collection, then the device speeds up and simplifies the process several times. The equipment allows you to cultivate a relatively large area of land in a short time.

What potato diggers exist for walk-behind tractors?

Depending on the design, diggers are divided into the following types:

- conveyor;

- thunderous;

- vibration;

- drum;

- fan;

- conveyor

Fan They called it so because its rods are arranged in the form of a fan. The main part of the mechanism is like a plow from which these rods extend. The principle of operation of a fan digger is simple: the plow goes into the ground, while the walk-behind tractor moves, the potatoes rise along the rods from the soil. The main advantages of this design are considered to be low cost and ease of manufacture. Among the disadvantages is the inability to use on hard soils.

At the roaring potato digger more complex design. It has additional wheels and support points. It also has a grate located at an angle to the surface of the earth. The grate is designed to remove excess soil. The main disadvantage is relatively low productivity.

Drum potato digger - a relatively complex mechanism that significantly speeds up and simplifies the process of collecting tubers. The plow is driven deep into the soil, the potatoes fall onto a grate, and then are sent into a rotating drum. There, the tubers undergo additional cleaning from the soil, and then end up in a box.

The main feature of the conveyor potato digger – presence of 2 main units. It consists of a conveyor that moves the potatoes and a ploughshare that lifts the soil layer.

Conveyor digger consists of a bucket with a conveyor belt in the center. The ladle lifts the potatoes along with the soil, after which they fall onto the belt. There, the tubers are cleared of soil residues and placed on the surface of the ground. The main advantage of a conveyor-type device is the ability to process several rows simultaneously.

What are the types of conveyor diggers?

Equipment for walk-behind tractors differs in design, size, working width and other criteria. But potato diggers are often divided based on their operating principle.

Diggers are:

- passive;

- active.

Conveyor potato diggers for walk-behind tractors are only active, since they have moving parts. The devices are connected using a shaft, gearbox or belt.

Advantages and disadvantages of a conveyor potato digger

The main advantages of the conveyor digger:

The main advantages of the conveyor digger:

- Potatoes are removed from the ground intact.

- Tuber losses are minimal.

- Potatoes are well cleaned from the soil.

- All moving mechanisms are on bearings.

The knife digs up the soil with the tubers and places it on the conveyor. On it, the potatoes are carefully peeled without getting damaged.

Disadvantages include high cost and large dimensions.

What are the advantages over other types

Conveyor diggers use a conveyor mechanism instead of vibration to clear soil. In addition, they additionally remove tops.

Such diggers are considered much more efficient than other types, but their cost is much higher. The dimensions of the device are more suitable for working in large areas. It can function in any weather.

Which potato digger is better - screen or conveyor?

In a potato digger, the tubers are cleared from the soil by vibration. Potatoes bounce, causing some damage to the crop. Screening units cope well with the task on light and medium soils.

If the soil is dense and heavy, it is advisable to use a conveyor potato digger - it is more reliable and efficient.Also, conveyor devices have a wider grip and a powerful frame.

How to choose the right one

The choice of potato digger is approached responsibly, as this is not cheap equipment.

When purchasing, consider:

- area of cultivated territory;

- soil structure;

- power and type of walk-behind tractor.

A conveyor device is usually purchased for large volumes of work. In small areas it is difficult to turn around with it.

Review of the best models of conveyor potato diggers for walk-behind tractors and their comparison

Nowadays there are a huge number of models of conveyor potato diggers on sale.

The most common and proven ones are presented below.

KK-11 (Poltava)

Produced in Ukraine. The main feature is high-quality and quick extraction of potatoes from the ground.

This model is suitable for Scout-type walk-behind tractors with a rear hydraulic system. It is also used on similar equipment with a power of 10 hp or more. With. Installation is carried out using a tow hitch, which is supplied in the kit.

The weight of the KK-11 is 65 kg, the working width is 45 cm. The steel grade is 45.

On average, this model is sold for 26,000 rubles.

Advantages:

- It quickly collects not only potatoes, but also garlic, onions, and beets.

- It is possible to adjust the depth.

- High build quality of the device.

- Reliability and long service life.

CAT-1 (MOLE)

The equipment is suitable for heavy-duty walk-behind tractors. This kind of digger is bought for large areas.

During manufacturing, high-quality steel is used, which gives additional reliability to the main components. The cost of the unit is about 27,000 rubles.

Main advantages:

- Reliability and durability.

- High quality build.

- Smooth running chain drive.

- Active knife.

- All possible adjustments are available.

- The conveyor belt is reinforced, which further increases the reliability of the structure.

- The weight of the unit is 55 kg with a working width of 46 cm.

KK-10

This model is considered effective and versatile, as it is capable of harvesting not only potatoes, but also most root vegetables. KK-10 exhibits maximum efficiency on areas up to 5 hectares.

The unit is designed for heavy walk-behind tractors. For work, it is important to first clear the area of tops and weeds. To prevent the potato digger conveyor from becoming clogged, the soil must be dry. But these shortcomings are compensated by increased reliability. The cost of the digger is 25,800 rubles.

KM-5

This is a popular model among farmers who cultivate both small plots and large areas. A belt is used as a drive. KM-5 is connected to walk-behind tractors with a power of 6 hp or more. With. with right or left belt drive.

The manufacturer guarantees high-quality assembly of all important components, including bearings. This model has a large number of different adjustments, thanks to which the farmer can easily adjust the equipment to the required conditions.

The cost of the KM-5 digger is 23,500 rubles.

This is interesting:

Review of potato planters for a walk-behind tractor and how to make it yourself

How to make a conveyor potato digger with your own hands

Make your own unit It's not very difficult to dig potatoes. The main thing is to do everything in accordance with pre-prepared drawings.

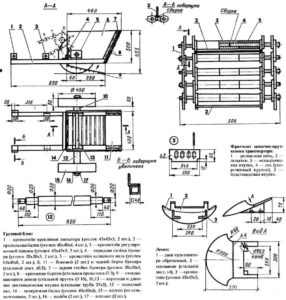

Drawings and dimensions

Some craftsmen themselves make drawings of future devices.But it is much easier to use ready-made materials that have already been used to make digging machines.

Examples are presented below.

Step-by-step instruction

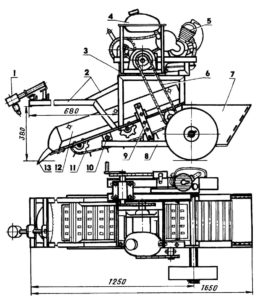

Step-by-step instructions for making a homemade conveyor single-row potato digger for the T-25:

- The frame is assembled from channels or metal corners. This is the basis of the entire future design, since the remaining components of the unit will be attached to the frame.

- The elevator is one of the most important and largest parts of the device. It includes a vibrating grill and sides, which are made of thick sheet metal. The structure is welded or bolted together.

- The elevator is equipped with special shafts to which the force from the wheels will be transmitted. This will cause the grate to vibrate.

- The next step is to secure the share. This is a plow that turns tubers out of the ground. The ploughshare is attached to the elevator with bolts.

- A support-transport unit is made. It includes rims, wheels, 2 roller chains, metal rod, bearings and sprockets.

- To make a conveyor belt for a potato digger, roller chains are used. The spikes at the junction of the links are removed. Instead, threaded studs are inserted and secured with nuts on both sides. There should be one chain on one side of the stud, and a second on the other.

- The stars are fixed on a metal rod that acts as a bridge. After this, the discs are welded, and the wheels are attached to them.

How to strengthen the Polish conveyor potato digger

In many models (for example, Wirax), the digging plow consists of 3 independent knives, i.e. the design is not monolithic. Because of this, the knives in such units quickly become deformed or break.

You can strengthen the Polish conveyor potato digger by welding a thick steel sheet - 4-5 mm - to the bottom of the ploughshare. After this, all excess is cut off so that its shape matches the shape of the knives. At the last stage, the front part of the new knife is sharpened using a grinder.

Tips and tricks

Basic tips for making and operating a potato digger:

- The unit is made only from durable and thick metal, since the device will experience heavy loads. All connections must be as reliable as possible.

- If possible, use bolted connections rather than welding. There is a possibility that the seams will burst due to vibration.

- It is advisable to always have several sets of knives. They often break, especially on hard soils.

Experts also say that it is better to harvest with an assistant. It is inconvenient and difficult to do the work alone.

Conclusion

The conveyor digger is considered one of the best varieties. It is used for medium and large areas.

For serious volumes of work, it is advisable to buy a factory-made device. But if the area is not very large, it is acceptable to use a homemade potato digger.