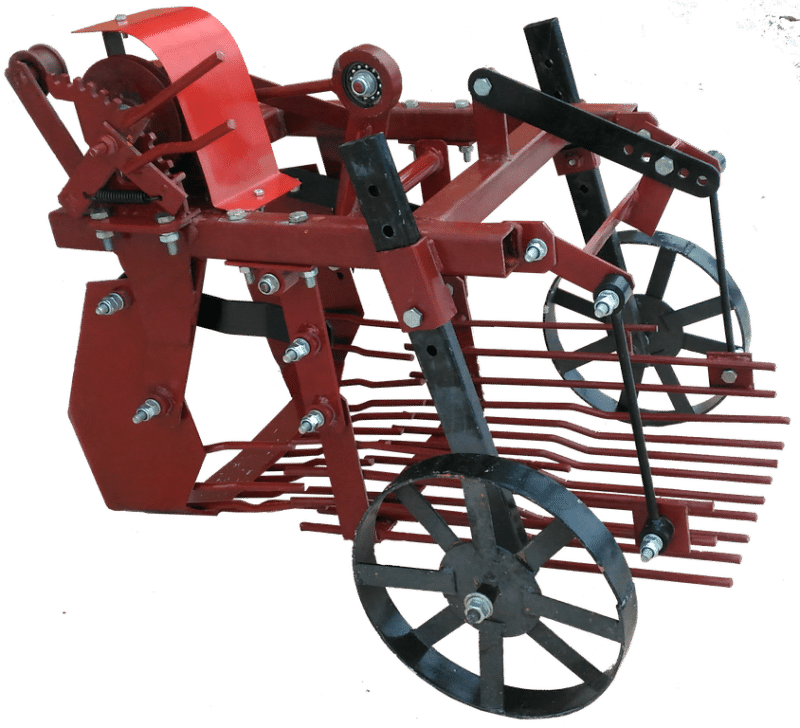

Model of potato digger KKM 1 for walk-behind tractor

Farms, owners of vegetable gardens and personal plots mechanize manual labor using walk-behind tractors. The potato crop is harvested using units attached to small tractors. The KKM-1 potato digger is a common mechanism among gardeners. Let's look at its characteristics and differences from other models of potato harvesting equipment.

Functionality and mechanism of action of the digger

The job of a potato digger is to dig its teeth into the soil to push the tubers to the surface. They are collected from the ground by hand.

Attachments KKM-1 belong to the active type of equipment vibration or rumbling action. Single-row model: processes 1 planting row of potatoes per pass.

Design and components of the structure

The mechanism frame is a spatial supporting frame welded from pipes and rolled profiles. Whole assembly attached to the walk-behind tractor. Main nodes

- plowshare knife;

- screen, or screening grid;

- chassis of 2 wheels: all-metal or with inflatable tires.

The potato digger is connected to the mini-tractor using a belt from the engine pulley. If there is no belt drive, a special adapter is provided. KKM-1 is combined with Neva walk-behind tractors, Salyut, Favorit, MTZ, Agat and others.

Principle of operation

The mechanism moves on support wheels, repeating the topography of the field. The immersion depth of the plowshare is adjusted by manipulating the hitch bracket and the wheel support struts.

How tubers are dug:

- The knife cuts off a layer of soil with vegetables, which are fed to a screen to screen out small material.

- The sieving grid breaks up clods of earth with vibrations, and the fines spill out between the rods. Horizontal vibrations are created by the eccentric shaft, rotated by a belt from the engine pulley.

- The over-sieve material of the screen rolls onto the ground behind the potato digger.

All that remains is to collect tubers ≥25 mm in size from the ground, cured from the depths.

Specifications

Optimal conditions for the operation of a potato digger: light and medium-hard (<20 kg/m²) soil with a humidity of less than 27%, the area is littered with stones - up to 800–900 g/m².

KKM-1 indicators:

- the speed of the tractor-digger coupling is 1–2.1 km/h;

- area processing productivity - 5–20 acres/hour;

- ploughshare immersion depth/width – 12–20/37 cm;

- screening grid rod spacing/Ø – 35/10 mm;

- machine dimensions (LxWxH) - 0.7x0.7x0.6 m;

- track - 600 mm;

- chassis dimensions: on tires - 330x90 mm, metal rims - 270x45 mm;

- weight - 40–45 kg depending on the wheel design and configuration.

The machine works in potato fields with row spacing of 60–70 cm. One operator is enough to control the walk-behind tractor with the connected KKM-1 unit.

Equipment

When delivering a potato digger to a retail chain, the parts necessary to connect the attached (trailer) equipment to the tractor are included:

- V-belt brand A-1180;

- small driving pulley - installed on the hub of the large pulley of the walk-behind tractor engine;

- fastening bolts, bushings;

- manual.

Hardware may not be included in the delivery set. There is no coupling device included.

Advantages and features of the KKM-1 model

Potato diggers for walk-behind tractors They are produced by many factories, the most famous brands being KKM and KVM.The KKM-1 modification repeats the advantages of other models in this series, in some ways it is inferior or superior to them.

Reference! KKM-1 is suitable for digging up beets, onions, and garlic.

The advantages of a rotary digger include reliability, resistance to adverse working conditions, and high speed of movement without damaging the tubers. The machine has adjustable digging depth. The disadvantage of the mechanism is poor sifting of wet soil.

Specifications of other units of the KKM series

All modifications of this series have similar characteristics, but there are also differences:

- KKM-2 — works in tandem with Agro, MTZ walk-behind tractors, and other mini-tractors, where the drive of additional equipment is provided through the power take-off shaft (PTO). The height of the machine is 100 mm higher than the size of KKM-1.

- KKM-3 - connects with mini tractor MTZ-132N and other tractors equipped with a PK3 PTO drive. The height of the potato digger is the same as that of KKM-2 - 700 mm, and the working width of the ploughshare - 400 mm versus 370 for KKM-1.

- KKM-4 — has larger dimensions than KKM-1: 800x700x920 mm. Works through a cardan from the PTO of a mini-tractor with a capacity of 9–16 hp. With. (KUBOTA, Mitsubishi, etc.). The working width is the same as that of KKM-3 - 400 mm.

The KKM-1 digger is more compact than each of the subsequent modifications, equipped with a drive from a power take-off shaft instead of a belt drive. At the same time, the performance characteristics of all machines are almost the same.

Differences from the KVM brand

The KKM-1 potato digger competes with the KVM-3 vibration digger with a belt drive, designed for digging up potatoes on heavy soils. The ability to work in more difficult conditions is provided by attaching an additional knife to the frame through an adapter, which creates additional vibration when cutting the ground.

Other differences between KVM-3 and KKM-1:

- lighter weight - 34–39 kg;

- compatible with walk-behind tractors with power ≥6 liters. With. (domestic and released in China, Japan);

- dimensions - 900×670×560 mm.

Arguments in favor of KVM-3: an additional knife for loosening heavy soils, compatibility with many types of walk-behind tractors.

Important! The pulley on the walk-behind tractor can be located on the right or left. KVM-3 can be connected in any way.

It’s impossible to say for sure which is better, KKM or KVM: KKM-1 is also aggregated with several brands of mini-tractors, and potatoes are rarely planted in unsuitable soil.

Potato digger cost

The price range for trailed units across Russian cities fluctuates within ±20%. Average prices by model can be seen using the example of the Akimov plant (Cheboksary, Chuvash Republic).

Current cost of potato diggers according to the enterprise catalog for May 2021, (thousand rubles):

- KKM-1 - 15.5 (for the Neva walk-behind tractor);

- KKM-2 - 16.5 (for Agro walk-behind tractor);

- KKM-3 - 17.5 (for the MTZ-132N mini-tractor);

- KKM-4 - 23.5 (for a mini-tractor).

The maximum price for an active digger KKM-1 S-Mash is 19.3 thousand rubles.

The cost of KVM-3 is usually 15–20% lower.

Recommendations for using the machine

Correct use of KKM-1 involves assessing the scope of upcoming work and setting up the mechanisms. Rational use of equipment is ensured on long stretches of the field with the tops removed in advance (1-2 days before digging).

During operation and when transporting the machine, it is recommended to follow the instructions in the operating manual:

- do not be in the path of a walk-behind tractor or potato digger;

- do not sit on the digger while moving it;

- remove the drive belt from the engine pulley when transporting the unit with a walk-behind tractor;

- make sure that guards and safety covers are in place before starting the mechanisms.

On light soils, the speed of movement must be increased, in hard soil - reduced.

Maintenance and cleaning of the screen from tops should be carried out only after the potato digger has completely stopped, with the walk-behind tractor engine turned off.

Equipment storage rules

In order not to lose the right to warranty repairs, it is important not only to follow the operating instructions, but also to properly store the potato digger. An indispensable condition for maintaining any equipment is cleaning the main components and mechanisms from dirt, plant debris, and soil.

Attention! Threaded surfaces, the axle of the wheel pair, and the potato digger blade are covered with grease if the unit will have to be stored until the next season.

After drying, the digger is rolled up for storage in a room protected from precipitation. Seasonal maintenance significantly extends the operating time of the unit.

Farmer reviews

When choosing an unfamiliar technique, gardeners strive to learn about its hidden shortcomings from various sources. To study the opinions of people who have already used the KKM-1 potato digger.

Here are some reviews we were able to find:

Andrey, Stavropol region: “It was made clumsily, but reliably. I didn’t find any grease on the joints of the digger, so I applied grease myself. Attached it to the Neva walk-behind tractor. In the field, the machine worked accurately: not a single tuber was damaged, and no potatoes were found in the ground. You can use it."

Mikhail, Bryansk region: “I bought KKM-1 from Cheboksary. Problems began when installing the pulley on the MB-1: the bolts and bushings from the kit turned out to be 15 mm shorter and had to be replaced. Belt A-1180 loosened - installed A-1120. Everything else is normal and works without flaws.”

Grigory, Omsk: “I’ve been working as a digger with a Neva-2 walk-behind tractor for 3 years now. The wheels are metal, and I attach 10 kg of weight to them. I'm digging on low.After each season I disassemble and lubricate the bushings. Not with a syringe, but each part separately. There were no breakdowns the entire time.”

This is interesting:

How to make a potato digger with your own hands: step-by-step instructions from A to Z

Advantages and disadvantages of growing potatoes using Dutch technology

Conclusion

The use of a potato digger makes harvesting less tedious: manual labor is aimed only at collecting tubers and root crops from the ground, and labor-intensive digging is performed by machinery. When purchasing a digger, it is important to pay attention to its compatibility with the walk-behind tractor or mini-tractor that the farmer has on his farm.